Machines may look powerful and solid from the outside, but their performance often depends on smaller moving parts working perfectly together. One such important part is the Poly V-strap. It may seem simple, but it carries a serious responsibility inside many mechanical systems.

Load capacity is one of the most important things engineers must understand before selecting or installing a strap. If the load is too high, failure becomes likely. If the load is too low, the system may not perform efficiently. So how do engineers determine the right balance? Let’s explore this step by step in simple and clear language.

What Does Load Capacity Actually Mean?

Load capacity refers to the amount of force or working pressure a strap can safely handle while the machine is running. It is not just about holding weight. It is about managing tension, rotation, speed, and power transfer all at the same time.

When a machine runs, the strap moves continuously around pulleys. It bends, stretches slightly, grips surfaces, and transfers energy from one part of the machine to another. If the load placed on it goes beyond its limit, the strap may slip, wear out faster, or even snap. This can stop production instantly.

Understanding this limit helps engineers prevent unexpected breakdowns and costly repairs.

Note:

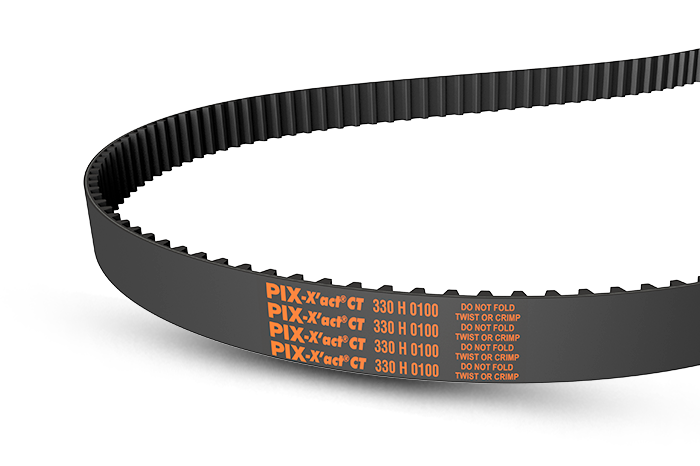

If you are reviewing your system requirements and want guidance on selecting the right Poly V-strap(Rippenriemen) for your application, PIX Germany provides technical insights and support. Contact them to better understand load compatibility and performance factors for your machinery.

Why Load Capacity Is So Important

Many machine failures do not happen because of large design mistakes. They happen because small components are overloaded over time. A strap working beyond its capacity may not fail immediately. Instead, it slowly weakens.

This can lead to higher energy use because the machine must work harder. It can cause vibration, noise, and overheating. In the worst cases, sudden failure may damage nearby components like bearings or pulleys.

By choosing the correct load capacity from the beginning, engineers protect the entire system, not just the strap.

Main Factors That Affect Load Capacity

Load capacity is not determined by one single feature. It depends on several connected factors.

Strap Width and Rib Design

A wider strap usually carries more load because the force spreads across a larger surface area. Multiple ribs increase grip and improve contact with the pulley. Better contact means better power transfer and less slipping.

However, simply choosing a wider strap is not always the solution. The pulley system must also match the design.

Material Strength

The internal material of the strap plays a huge role. Strong internal cords provide stability and prevent stretching. The outer layer must stay flexible while resisting wear.

When materials are strong and well-designed, they allow the strap to carry more load safely for longer periods.

Pulley Size

Pulley diameter strongly affects stress levels. Smaller pulleys force the strap to bend more sharply. This creates additional stress and reduces load capacity over time.

Larger pulleys allow smoother movement and reduce bending stress. This often improves durability and performance.

Speed of Operation

Speed adds another layer of stress. At higher speeds, friction increases and heat builds up. Even if the load appears safe at lower speeds, it may become risky when the machine runs faster.

This is why engineers must always consider both speed and load together.

Tension and Alignment

Correct tension is essential. If the strap is too tight, it creates extra stress and may damage bearings. If it is too loose, slipping occurs and power transfer becomes inefficient.

Alignment is equally important. Even slight misalignment can reduce effective load capacity and increase uneven wear.

How Different Conditions Influence Load Capacity

Below is a simplified comparison of how operating conditions impact performance.

| Condition | Impact on Load Handling | Overall Effect |

|---|---|---|

| Proper alignment | Full surface contact | Stable and efficient |

| Slight misalignment | Uneven pressure | Reduced lifespan |

| Excessive tension | High internal stress | Early wear |

| Correct tension | Balanced force | Longer service life |

| Large pulley diameter | Reduced bending stress | Higher durability |

| Small pulley diameter | Increased bending strain | Lower capacity |

This table shows how small changes in setup can strongly affect load handling.

How Engineers Estimate Required Load

Engineers calculate load requirements carefully rather than guessing. They study how much power the machine needs and how fast it runs. They also check pulley sizes and working hours.

Environmental factors such as temperature and dust exposure are considered as well. After gathering all this information, they apply a safety margin. This means they select a strap that can handle slightly more load than required. The reason is simple: real-life conditions are rarely perfect.

This careful planning reduces the risk of unexpected breakdowns.

Environmental Conditions That Change Load Capacity

The surrounding environment can quietly reduce performance over time.

Heat

High temperatures can weaken materials and increase wear. Continuous heat exposure may slowly reduce strength, even if the load stays constant.

Dust and Debris

Dust particles can enter the contact area between the strap and pulley. This increases friction and uneven wear. Over time, this reduces the strap’s ability to carry load effectively.

Moisture

Moist conditions may affect grip and cause slipping. In some environments, moisture may also influence material stability.

Engineers must always think about where the system will operate, not just how much load it carries.

Quick Comparison of Load Capacity Influencers

| Factor | Improves Performance | Reduces Performance |

|---|---|---|

| Alignment | Precise setup | Misalignment |

| Temperature | Normal range | Excessive heat |

| Tension | Correct adjustment | Too tight or too loose |

| Pulley Size | Larger diameter | Smaller diameter |

| Material Quality | Strong construction | Weak internal support |

This comparison makes it easier to understand which areas need attention during installation and maintenance.

Warning Signs of Overloading

Overloading does not always show immediate signs. Sometimes it builds slowly. Engineers and maintenance teams should watch for surface cracks, frayed edges, shiny areas on ribs, unusual noise, or increased vibration.

These signs often indicate that the load or tension needs review. Ignoring them can lead to sudden failure.

The Long-Term Cost of Ignoring Load Limits

When load capacity is ignored, costs increase in hidden ways. Energy use rises because the system struggles to transfer power smoothly. Components wear out faster. Downtime becomes more frequent.

Over time, these small issues turn into major expenses. Understanding load capacity early saves both time and money.

Final Thoughts

Load capacity is more than just a technical number. It represents balance. Power, speed, pulley size, tension, and environment all work together. If one factor is ignored, the entire system may suffer.

When engineers understand how load capacity works, they create safer, more reliable machines. And often, the difference between smooth performance and sudden failure comes down to this single calculation.

FAQs

1. What happens if load capacity is exceeded?

If the load exceeds the limit, the strap may stretch, slip, overheat, or break. This can also damage other machine parts.

2. Does higher speed reduce load capacity?

Yes. Higher speed increases heat and stress, which can lower the safe load limit.

3. How often should load conditions be reviewed?

Load conditions should be checked during installation and reviewed during regular maintenance inspections.

4. Can pulley size really affect load capacity?

Yes. Larger pulleys reduce bending stress and usually support better performance.

5. Why is correct tension important?

Correct tension ensures smooth power transfer and prevents extra stress on both the strap and machine components.

Connect With PIX Germany

Facebook: https://www.facebook.com/pixgermanygmbh/

Instagram: https://www.instagram.com/pixgermanygmbh/

YouTube: https://www.youtube.com/user/pixtrans

LinkedIn: https://www.linkedin.com/company/pixgermanygmbh/

Twitter (X): https://x.com/pixgermanygmbh

Google Maps: https://maps.app.goo.gl/Ls83bzangT1ipdQv5