When it comes to heavy-duty rubber belts, the material makes all the difference. The right material can improve performance, reduce downtime, and save money over time. The wrong one? It can lead to cracks, wear, frequent replacements, and unexpected shutdowns.

But here’s the real question: How do you know which material is truly right for your needs?

Many people assume all rubber belts are the same. They are not. Each material has unique strengths and weaknesses. Some handle heat better. Some resist oil. Others are built for rough and sharp materials.

In this guide, we’ll compare the top five heavy-duty rubber belt materials in simple and clear language. By the end, you’ll have a better idea of which one fits your situation best.

Note:

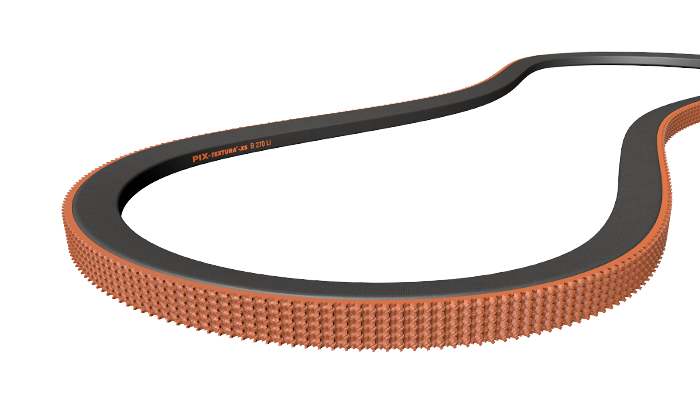

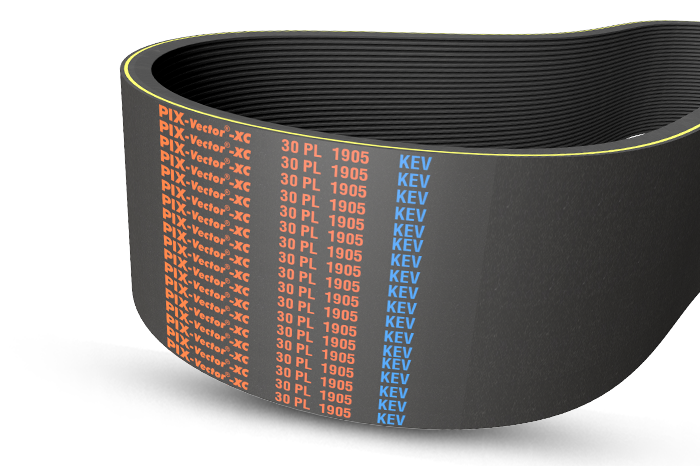

If you are exploring durable solutions like Special construction rubber belts(สายพานยางสำหรับงานก่อสร้างพิเศษ) and want guidance from industry experts, PIX Trans Thailand can provide helpful insights based on your specific needs. Contact them to understand which material suits your application best.

Why Material Choice Matters More Than You Think

Heavy-duty rubber belts work in tough conditions. They may carry rocks, sand, cement, coal, grain, or industrial products. They may operate in extreme heat, freezing cold, or wet and oily environments.

If the material is not suitable, you may face:

- Faster wear and tear

- Frequent belt replacement

- Lower efficiency

- Higher maintenance costs

- Unexpected downtime

Choosing the right material is not just about strength. It’s about matching the belt to the environment it works in.

Let’s explore the five most common materials used in heavy-duty rubber belts.

1. Natural Rubber (NR)

Natural rubber is one of the oldest and most widely used materials for heavy-duty belts.

What Makes It Popular?

Natural rubber is known for its flexibility and strong grip. It can handle heavy loads and repeated movement without cracking easily.

Main strengths:

- Excellent flexibility

- Strong resistance to wear

- Good grip on materials

- Works well in dry conditions

Where It Works Best

Natural rubber is ideal for industries where materials are rough but not oily. It performs well in mining, sand handling, and general construction work.

Where It Struggles

It does not perform well when exposed to oil, grease, or high heat for long periods. In those conditions, it may swell or weaken.

2. Styrene-Butadiene Rubber (SBR)

SBR is often used as a cost-effective alternative to natural rubber. It offers similar benefits but at a lower cost.

Why People Choose It

SBR provides good resistance to wear and handles moderate temperatures well.

Main strengths:

- Affordable option

- Good wear resistance

- Performs well in dry environments

- Suitable for general use

Limitations to Consider

SBR does not handle oil exposure well. It also has slightly lower strength compared to natural rubber.

If you need a budget-friendly solution for general material transport, SBR can be a practical choice.

3. Nitrile Rubber (NBR)

Now things get interesting. Nitrile rubber stands out for one major reason: oil resistance.

What Makes It Different?

If your belt operates in areas with oil, grease, or fuel, nitrile rubber may be the right option.

Main strengths:

- Excellent oil resistance

- Good strength

- Handles moderate heat

- Long lifespan in oily conditions

Ideal Applications

Food processing plants, recycling centers, and industries where oil contact is common often prefer nitrile rubber belts.

However, nitrile rubber may not be as flexible as natural rubber.

4. EPDM Rubber (Ethylene Propylene Rubber)

EPDM rubber is known for its ability to handle extreme weather and heat.

Why It Stands Out

If your operations involve high temperatures or outdoor exposure, EPDM can perform better than many other materials.

Main strengths:

- Excellent heat resistance

- Strong resistance to weather and sunlight

- Good performance in wet conditions

- Long life in outdoor environments

When to Use EPDM

EPDM is commonly used in cement plants, outdoor conveyor systems, and high-temperature areas.

It is not suitable for heavy oil exposure.

5. Neoprene Rubber (CR)

Neoprene is a balanced material. It offers moderate oil resistance, good weather resistance, and solid strength.

Why It’s Versatile

Neoprene works well when you need a mix of properties.

Main strengths:

- Moderate oil resistance

- Good weather protection

- Reliable strength

- Handles different environments

The Trade-Off

It may cost more than natural rubber or SBR, but it provides more balanced protection.

Quick Comparison of the Five Materials

Here is a clear overview to help you compare them easily:

| Material | Best Feature | Handles Oil? | Handles Heat? | Ideal For |

|---|---|---|---|---|

| Natural Rubber | Flexibility & wear resistance | No | Moderate | Mining, dry materials |

| SBR | Affordable & durable | No | Moderate | General transport |

| Nitrile (NBR) | Oil resistance | Yes | Moderate | Oily environments |

| EPDM | Heat & weather resistance | No | Yes | Outdoor & hot areas |

| Neoprene | Balanced performance | Moderate | Moderate | Mixed environments |

How to Choose the Right Material for Your Needs

Before making a decision, ask yourself these important questions:

- Will the belt come in contact with oil or grease?

- Is the environment hot or exposed to sunlight?

- Are the materials sharp or heavy?

- Is flexibility important?

- Are you looking for a budget option or long-term durability?

Here’s a simple guide to narrow it down:

| Your Condition | Recommended Material |

|---|---|

| Heavy dry materials | Natural Rubber |

| Budget-friendly option | SBR |

| Oil exposure | Nitrile |

| High heat or outdoor use | EPDM |

| Mixed conditions | Neoprene |

The Hidden Factor Most People Ignore

Many buyers focus only on price. But here’s the truth: The cheapest belt is not always the most affordable in the long run.

A belt that fails frequently can cause:

- Production delays

- Extra labor costs

- Emergency repairs

- Safety risks

Choosing the right material from the start can reduce these risks.

Final Thoughts: Which One Is Truly Right for You?

There is no single “best” material for everyone. The right choice depends on your working conditions.

- If flexibility and strength matter most → Natural Rubber

- If cost matters most → SBR

- If oil exposure is constant → Nitrile

- If heat and weather are major concerns → EPDM

- If you need balanced protection → Neoprene

Take time to evaluate your environment carefully. A small decision today can prevent major problems tomorrow.

Frequently Asked Questions (FAQ)

1. Which rubber belt material lasts the longest?

It depends on the working condition. In dry environments, natural rubber may last long. In oily areas, nitrile performs better.

2. Can one material handle both heat and oil?

Neoprene can handle moderate levels of both, but no single material is perfect for extreme conditions.

3. Is a more expensive belt always better?

Not always. The key is matching the material to your environment.

4. How do I know if oil resistance is necessary?

If your belt regularly touches oil, grease, or fuel, oil resistance is very important.

5. What is the safest option for outdoor use?

EPDM is generally the safest choice for outdoor and high-temperature environments.

Connect With Us

Facebook: https://www.facebook.com/pixtrans/

Instagram: https://www.instagram.com/pixtrans/

YouTube: https://www.youtube.com/user/pixtrans

LinkedIn: https://www.linkedin.com/company/pixtrans/

Twitter (X): https://x.com/pixtrans

Google Maps: https://maps.app.goo.gl/V2NG4NKaZRKu7xtG6