In many factories and production units, machines must run smoothly every single day. For years, chain drives were the common choice to move power from one part of a machine to another. They were strong, simple, and widely used.

But today, something is changing. More industries are quietly shifting toward a different solution. The question is—why are so many businesses replacing chains with belts?

The answer may surprise you. Let’s explore what is really happening inside modern factories and why this shift is growing so fast.

Understanding Traditional Chain Drives

Chain drives have been used in industries for a long time. They work by using metal chains that connect rotating shafts. When one shaft moves, the chain pulls the other shaft along with it.

How Chain Drives Work

- A metal chain connects two sprockets

- As one sprocket rotates, the chain moves

- The second sprocket turns, transferring power

Chains are strong and can carry heavy loads. That is why they were trusted for many years in industries like agriculture, manufacturing, and heavy machinery.

Common Problems with Chain Drives

Even though chains are strong, they come with several challenges:

- Regular lubrication is needed

- Noise during operation

- Wear and tear over time

- Frequent maintenance

- Risk of rust in wet conditions

These issues may seem small at first. But over time, they increase maintenance costs and machine downtime.

And downtime is something no factory wants.

What Are Industrial Synchronous Belts?

Now let’s look at the alternative.

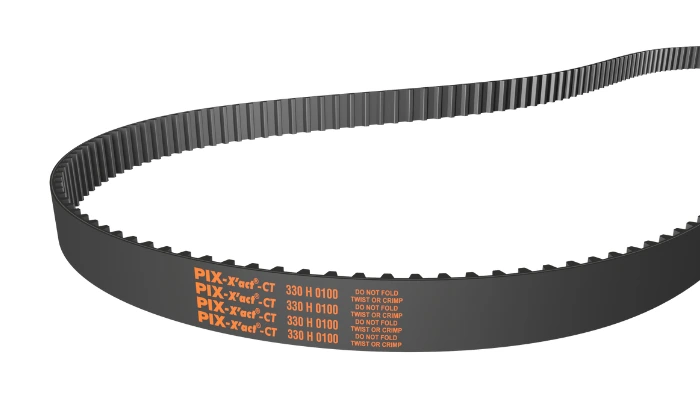

Industrial synchronous belts are toothed belts designed to move in sync with machine pulleys. The teeth on the belt fit perfectly into grooves on the pulley. This creates smooth and accurate movement without slipping.

Unlike chains, these belts are usually made from strong rubber materials with internal cords for added strength.

How They Work

- The belt has teeth

- The pulley has matching grooves

- Teeth lock into grooves

- Power moves smoothly without slipping

Because of this design, the belt and pulley move together in perfect timing. That is why they are called “synchronous.”

If you are exploring advanced power transmission options, learning more about Industrial Synchronous Belts can help you make informed decisions for your machinery needs. For detailed information and expert guidance, you may reach out to Pix transmission. Contact them to understand how modern belt systems can support your industrial operations.

Key Differences Between Chain Drives and Synchronous Belts

Here is a clear comparison to understand why industries are making the switch.

| Feature | Chain Drives | Synchronous Belts |

|---|---|---|

| Material | Metal | Rubber with strong cords |

| Lubrication | Required regularly | Not required |

| Noise Level | Noisy | Quiet |

| Maintenance | High | Low |

| Rust Risk | Yes | No |

| Clean Operation | Can be messy | Clean and dry |

| Energy Efficiency | Moderate | Higher |

Looking at this table, the benefits start to become clear. But there is more.

Why Industries Are Making the Shift

Many factory owners once believed chains were the only strong solution. So what changed?

1. Lower Maintenance Costs

Chains need oil. They need cleaning. They need adjustment.

Belts do not require lubrication. This means:

- Less time spent on maintenance

- Lower cost of servicing

- Reduced machine downtime

Over a year, these small savings add up to a big amount.

2. Quieter Work Environment

Factories can be loud. Machines already produce noise from motors and gears.

Chain drives add extra sound because metal hits metal.

Synchronous belts operate quietly. This helps:

- Improve working conditions

- Reduce noise pollution

- Create a safer environment

In many industries today, noise control is becoming very important.

3. Better Energy Efficiency

Here is something many people do not expect.

Chains can lose energy due to friction and misalignment.

Belts, especially toothed belts, transfer power smoothly. This means:

- Less energy loss

- Better performance

- Lower electricity consumption

Over time, this improves overall machine efficiency.

4. Cleaner Operation

In industries like food processing, packaging, and pharmaceuticals, cleanliness is critical.

Chains require oil. Oil can leak. Dust can stick to oily surfaces.

Synchronous belts work without oil. This makes them a better choice for clean environments.

Performance Comparison in Real-World Conditions

To understand the difference better, look at how both systems perform under common factory conditions.

| Condition | Chain Drive Performance | Synchronous Belt Performance |

|---|---|---|

| High Speed | Can become noisy | Smooth and stable |

| Wet Environment | Risk of rust | No rust |

| Dusty Area | Oil attracts dust | Dry operation |

| Long Working Hours | Needs frequent checks | Longer service intervals |

| Alignment Issues | Can stretch and loosen | Maintains accurate timing |

This comparison explains why many industries are reconsidering old systems.

Are Belts Strong Enough?

One common concern is strength.

People often think metal chains must be stronger than rubber belts. But modern belts are designed with strong internal cords made from materials that can handle heavy loads.

These belts are built to:

- Handle high torque

- Maintain accurate timing

- Resist stretching

- Last for long periods

The idea that belts are weak is slowly disappearing.

Where This Change Is Happening

Industries adopting synchronous belts include:

- Food processing plants

- Packaging units

- Textile factories

- Printing machines

- Automotive production lines

In many cases, companies that test belts once rarely go back to chains.

The Future of Power Transmission

Technology keeps moving forward. Machines are becoming faster, more precise, and more energy efficient.

Older systems that require heavy maintenance are slowly being replaced by cleaner and smarter solutions.

The shift from chains to belts is not sudden. It is gradual but steady. And it is happening because industries want:

- Lower operating costs

- Less downtime

- Better efficiency

- Cleaner production areas

- Quieter machines

When multiple benefits come together in one solution, change becomes natural.

Final Thoughts

Chain drives played an important role in industrial history. They were reliable and strong for many decades.

But as industries demand better efficiency, cleaner environments, and reduced maintenance, synchronous belts are proving to be a practical alternative.

The real reason behind this shift is simple—businesses want solutions that save time, reduce costs, and improve performance without extra effort.

And once factories experience these advantages, the decision becomes clear.